No products in the cart.

Home / All In

Engineered to perfect grinding

All Dip grinders, have been oriented to work simply and efficiently without compromising the grinding quality.

From the very foundation of the company, we insisted on producing every core component of our machines inside the factory.

To support this principle, all tolls and moulds are designed and produced also by us, being designed with respect to the principles of proper engineering.

Quality Control

Every single machine that goes out from our factory is carefully tested in order to ensure long term functionality.

From the very first drawing our grinders are designed for easy functioning and maintenance, making them every roaster’s or coffee shop’s best friend.

Our products do not claim, but prove our devotion to Perfect Grinding.

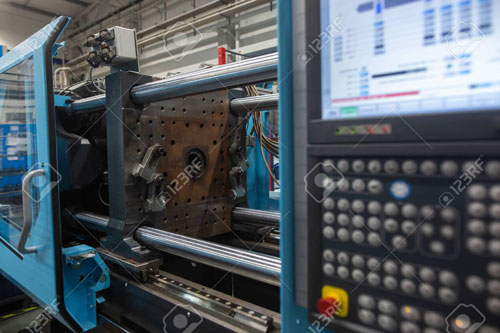

Injection Moulding

Injection moulding for all plastic parts is also done in our premises. With great respect to the principles of engineering, Dip grinders carry plastic parts which are manufactured in proper conditions, with top quality tooling.

Grinding discs

You cannot have a good grinding quality without controlling the quality of the grinding discs.

Carefully designed and cured, all our burrs can be re-sharpened 2 or 3 times if installed and used properly.

A faire cost is also important. It makes no sense to have a good grinder if you cannot afford to keep its burrs in proper condition.

Engineered to perfect grinding

All Dip grinders, have been oriented to work simply and efficiently without compromising the grinding quality.

From the very foundation of the company, we insisted on producing every core component of our machines inside the factory.

To support this principle, all tolls and moulds are designed and produced also by us, being designed with respect to the principles of proper engineering.

Quality Control

Every single machine that goes out from our factory is carefully tested in order to ensure long term functionality.

From the very first drawing our grinders are designed for easy functioning and maintenance, making them every roaster’s or coffee shop’s best friend.

Our products do not claim, but prove our devotion to Perfect Grinding.

Injection Moulding

Injection moulding for all plastic parts is also done in our premises. With great respect to the principles of engineering, Dip grinders carry plastic parts which are manufactured in proper conditions, with top quality tooling.

Grinding discs

You cannot have a good grinding quality without controlling the quality of the grinding discs.

Carefully designed and cured, all our burrs can be re-sharpened 2 or 3 times if installed and used properly.

A faire cost is also important. It makes no sense to have a good grinder if you cannot afford to keep its burrs in proper condition.